It is well established that the sinking of Titanic was the result of an iceberg collision, which fatally punctured the ship's five forwardmost watertight compartments. Less obvious, however, are the reasons for the collision itself (which occurred on a clear night, and after the ship had received numerous ice warnings), the factors underlying the sheer extent of the damage sustained by the ship, and the reasons for the extreme loss of life.

Construction and metallurgy

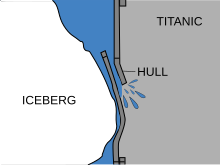

Originally, historians thought the iceberg had cut a gash into Titanic's hull. Since the part of the ship that the iceberg damaged is now buried, scientists used sonar to examine the area and discovered the iceberg had caused the hull to buckle, allowing water to enter Titanic between her steel plates.The steel plate used for Titanic's hull was of 1 to 1½ inch (2.5 to 3.8 cm) thickness. A detailed analysis of small pieces of the steel plating from Titanic found that it was of a metallurgy that loses its ductility and becomes brittle in cold or icy water, leaving it vulnerable to dent-induced ruptures. The pieces of steel were found to have very high content of phosphorus and sulphur (4× and 2× respectively, compared with modern steel), with manganese-sulphur ratio of 6.8:1 (compared with over 200:1 ratio for modern steels). High content of phosphorus initiates fractures, sulphur forms grains of iron sulphide that facilitate propagation of cracks, and lack of manganese makes the steel less ductile. The recovered samples were found to be undergoing ductile-brittle transition in temperatures of 90 °F (32 °C) for longitudinal samples and 133 °F (56 °C) for transversal samples, compared with transition temperature of −17 °F (−27 °C) common for modern steels: modern steel would only become so brittle in between −76 °F and −94 °F (−60 °C and −70 °C). Titanic's steel, although "probably the best plain carbon ship plate available at the time", was thus unsuitable for use at low temperatures. The anisotropy was probably caused by hot rolling influencing the orientation of the sulphide stringer inclusions. The steel plate for Titanic was supplied by David Colville & Sons using acid-lined, open hearth furnaces at their Dalzell Steel and Iron Works in Motherwell near Glasgow, which would explain the high content of phosphorus and sulphur, even for the time. But it seems highly probable that this brittle steel sample used for the analysis above was not all representative for the ship as it was a fractured part out of the debris field, probably making it a "self-selected" sample of worst quality. Newer analysis, using slow bend tests on six hull samples at room temperature and at 0°C, suggest that Titanic's hull steel was by no means a brittle material, even at ice-brine temperatures.

Another factor was the rivets holding the hull together, which were much more fragile than once thought. From 48 rivets recovered from the hull of Titanic, scientists found many to be riddled with high concentrations of slag. A glassy residue of smelting, slag can make rivets brittle and prone to fracture. Records from the archive of the builder show that the ship's builder ordered No. 3 iron bar, known as "best"—not No. 4, known as "best-best", for its rivets, although shipbuilders at that time typically used No. 4 iron for rivets. Rivets of "best best" iron had a tensile strength of approximately 80% of steel's; "best" iron was only around 73%. The company also had shortages of skilled riveters, particularly important for hand riveting, which took great skill: the iron had to be heated to a precise colour and shaped by the right combination of hammer blows. The company used steel rivets, which were stronger and could be installed by machine, on the central hull, where stresses were expected to be greatest, using iron rivets for the stern and bow. Despite this, the most extensive and finally fatal damage the Titanic sustained, at boiler rooms No. 5 and 6, was done in an area where steel rivets were used.

Rudder construction and turning ability

Although Titanic's rudder met the mandated dimensional requirements for a ship her size, the rudder's design might not have reflected contemporary design standards. According to research by BBC History: "Her stern, with its high graceful counter and long thin rudder, was an exact copy of an 18th-century sailing ship... a perfect example of the lack of technical development. Compared with the rudder design of the Cunarders, Titanic's was a fraction of the size. No account was made for advances in scale and little thought was given to how a ship, 852 feet in length, [sic] might turn in an emergency or avoid collision with an iceberg. This was Titanic's Achilles heel." A more objective assessment of the rudder provision compares it with the legal requirement of the time: the area had to be within a range of 1.5% and 5% of the hull's underwater profile and, at 1.9%, Titanic was at the low end of the range. However, the tall rudder design was more effective at the vessel's designed cruising speed; short, square rudders were more suitable for low-speed manoeuvring. In fairness to the Harland & Wolff designers and a challenge to the speculative theory that the rudder was ineffective, can be related an incident that happened on the Olympic in 1918 during World War One. The Olympic using the same semi-oval shaped rudder as Titanic's was able to turn in a virtual moment's notice to avoid an enemy submarine and in turn chase down the opposing submarine, ram it and sink it.Perhaps more fatal to the design of Titanic was her triple screw engine configuration, which had reciprocating steam engines driving her wing propellers, and a steam turbine driving her centre propeller. The reciprocating engines were reversible, while the turbine was not. According to subsequent evidence from Fourth Officer Joseph Boxhall, who entered the bridge just after the collision, First Officer Murdoch had set the engine room telegraph to reverse the engines to avoid the iceberg, thus handicapping the turning ability of the ship. Because the centre turbine could not reverse during the "full speed astern" manoeuvre, it was simply stopped. Since the centre propeller was positioned forward of the ship's rudder, the effectiveness of that rudder would have been greatly reduced: had Murdoch simply turned the ship while maintaining her forward speed, Titanic might have missed the iceberg with metres to spare. Another survivor, Frederick Scott, an engine room worker, gave contrary evidence: he recalled that at his station in the engine room all four sets of telegraphs had changed to "Stop", but not until after the collision.

Orientation of impact

It has been speculated that the ship could have been saved if she had rammed the iceberg head on. It is hypothesised that if Titanic had not altered her course at all and instead collided head first with the iceberg, the impact would have been taken by the naturally stronger bow and damage would have affected only one or two forward compartments. This would have disabled her, and possibly caused casualties among the passengers near the bow, but probably would not have resulted in sinking since Titanic was designed to float with the first four compartments flooded. Instead, the glancing blow to the starboard side caused buckling in the hull plates along the first five compartments, more than the ship's designers had anticipated.Weather

The weather for the Atlantic at the time of the collision was unusual because there was a flat calm sea, without wind or swell. In addition, it was a moonless night. Under normal sea conditions in the area of the collision, waves would have broken over the base of an iceberg, assisting in the location of icebergs even on a moonless night. The temperature dropped from about 43° Fahrenheit (6° Celsius) to near freezing, giving difficulty for the lookouts. The northwest winds behind the front helped to steer a giant ice field toward the ships.Excessive speed

The conclusion of the British Inquiry into the sinking was “that the loss of the said ship was due to collision with an iceberg, brought about by the excessive speed at which the ship was being navigated”. At the time of the collision it is thought that Titanic was at her normal cruising speed of about 21 knots (39 km/h), which was less than her top speed of around 23 knots (43 km/h). At the time it was common (but not universal) practice to maintain normal speed in areas where icebergs were expected. It was thought that any iceberg large enough to damage the ship would be seen in sufficient time to be avoided. It is often alleged that J. Bruce Ismay instructed or encouraged Captain Smith to increase speed in order to make an early landfall, and it is a common feature in popular representations of the disaster, such as the 1997 film, Titanic. There is little evidence for this having happened, and it is disputed by many.Alternative theories

Main article: Titanic alternative theories

A number of alternative theories diverging from the standard explanation for Titanic's demise have been brought forth since shortly after the sinking. Some of these include a coal fire aboard ship, or Titanic hitting pack ice rather than an iceberg. In the realm of the supernatural, it has been proposed that Titanic sank due to a mummy's curse.

0 comments:

Post a Comment